- Unicorner

- Posts

- OSSTEC

OSSTEC

3D-printed bone implants

We’ll preface this week’s startup cover by saying: we’re in our twenties. And our bones and joints are still working quite well (for now).

But if you’re reading this and do have such troubles (to the extent of even having, say, a recent joint replacement), then our coverage of OSSTEC and the problem it’s solving should come as no surprise.

And if you’re using the old joint replacement techniques, according to OSSTEC? We might as well drop this legendary Got Milk? x Jeopardy collab (RIP Alex Trebek).

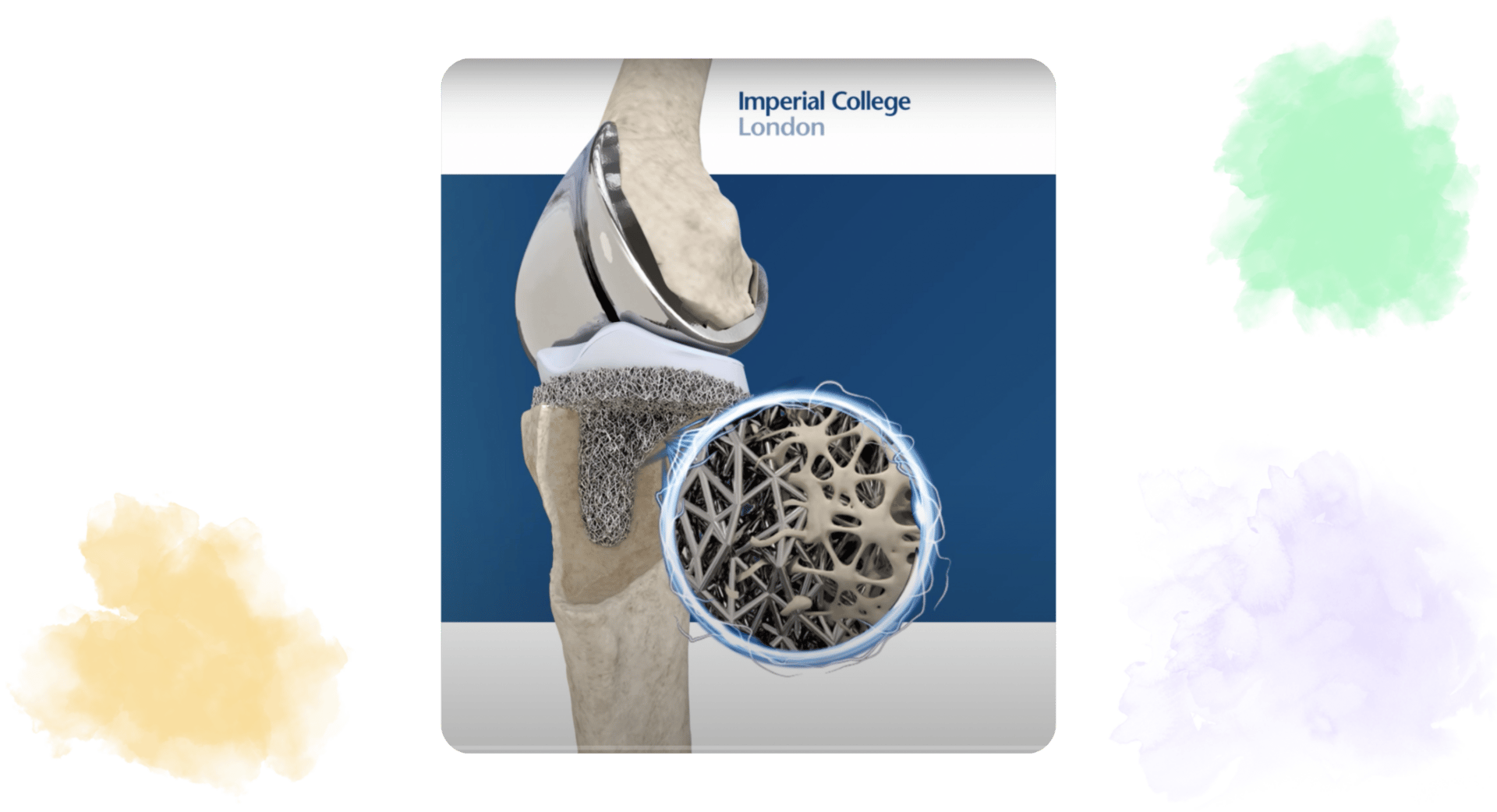

Joint replacement implants are traditionally anchored to bone using a cement called PMMA. However, this method is prone to loosening and long-term complications. OSSTEC addresses this problem by developing cementless bone implants that promote stable, natural anchoring. Its proprietary 3D printing process creates a highly porous titanium lattice that closely mimics the spongy architecture of bone, which enables bone tissue to grow into and interlock with the implant, resulting in durable biological fixation and improved long-term outcomes. The company also provides custom surgical instruments and training platforms to help surgeons implement their implants.

Check it out: osstec.uk

OSSTEC sells directly to hospitals, surgery centers, and medical practitioners.

Raised £2.5 million ($2.9 million) seed round from SFC Capital, Empirical Ventures, Embryo Ventures, Oxford Innovation Finance, and Mishcon de Reya

Awarded Innovate UK grant in collaboration with Nexus Additive

Conducted a study on human cadavers demonstrating effectiveness of proprietary technology

Dr. Max Munford recognized engineering's transformative potential in the medical field after studying mechanical engineering at Imperial College London and interning at medical device companies. Equipped with this insight and an entrepreneurial drive, he returned to Imperial College with the vision of pursuing a PhD and spinning his research into a company. Here, he studied under Dr. Jonathan Jeffers, whose research focused on 3D printing metals and advanced materials that could replicate bone's natural properties.

The path for commercialization became clear when Munford partnered with Alex Liddle, a surgeon performing hundreds of hip and knee surgeries annually, and identified a critical challenge in cementless fixation: the need for implants that work harmoniously with bone's natural biomechanics. Together, they realized that their advanced 3D metal printing research could address this orthopedic challenge, ultimately laying the footing for OSSTEC.

OSSTEC is positioned to succeed in the orthopedic implant industry due to a combination of its pioneering manufacturing process and highly favorable market dynamics.

Currently, orthopedic implants demand complex, multi-step manufacturing. This begins with manufacturing the basic structure, then creating porous surfaces for bone attachment, and finally machining smooth articulating surfaces where joint components move. In contrast, OSSTEC 3D-prints both the porous, bone-anchoring and smooth, low-friction parts of the implant at the same time. This not only reduces costs and production time but also enables greater product consistency and new design possibilities that are difficult with conventional techniques.

A close-up view of OSSTEC’s 3D-printed bone implants.

A growing senior population directly expands the market opportunity for OSSTEC, as seniors are the primary recipients of joint replacement surgeries. According to the U.S. Census Bureau, all baby boomers are expected to be aged 65 or older by 2030, and currently, approximately 10,000 Americans are turning 65 each day. This demographic shift means a significant increase in patients requiring joint replacement surgeries, especially knee and hip replacements, which are the most common procedures among seniors. The global knee replacement market alone is projected to exceed $13 billion by 2032, growing at a compound annual growth rate (CAGR) of 5%.

Moreover, revision arthroplasties, or joint replacement surgeries, represent a significant financial burden. In the U.S. alone, the number of revision knee procedures is projected to increase by 66%, reaching nearly 57,000 cases by 2030, with hospital costs expected to exceed $2 billion. Despite this growing burden, reimbursement rates remain insufficient to cover hospital costs, even with recent increases in Medicare payments for revision arthroplasty. As a result, if OSSTEC’s implants can demonstrate improved durability and lower failure rates, they could offer meaningful cost savings for hospitals and reduce the need for costly revision surgeries, benefiting both providers and patients.

Finally, OSSTEC is looking to expand its clinical applications. According to Dr. Max Mumford, OSSTEC’s CEO, the company aims to adapt its core 3D-printing technology for use beyond the knee market.

“It’s a technology… which can be used across multiple other implants for patient benefit.”

While there is much left for OSSTEC to overcome in terms of clinical trials and market adoption, it is in a unique position to reshape orthopedic care by combining a disruptive manufacturing process, growing market demand, and a strong economic value proposition.

Imperial College London: Research on 3D-Printed Bone Implants [Imperial]

Publications [OSSTEC]

Is this week's company a future unicorn? |