- Unicorner

- Posts

- DeepCorner: Advanced Materials

DeepCorner: Advanced Materials

Why advanced materials are key to DeepTech

Welcome to our first (non-kickoff) article of 2026.

We’re starting the year off with a departure from our usual weekly content, instead presenting you with a deep dive into deep tech.

That’s right. It’s a new edition of our DeepCorner series.

Writer Kanay Shah is back this week with full context on advanced materials and their place in technological innovation.

Missed the last editions of DeepCorner? Check out our write-ups on:

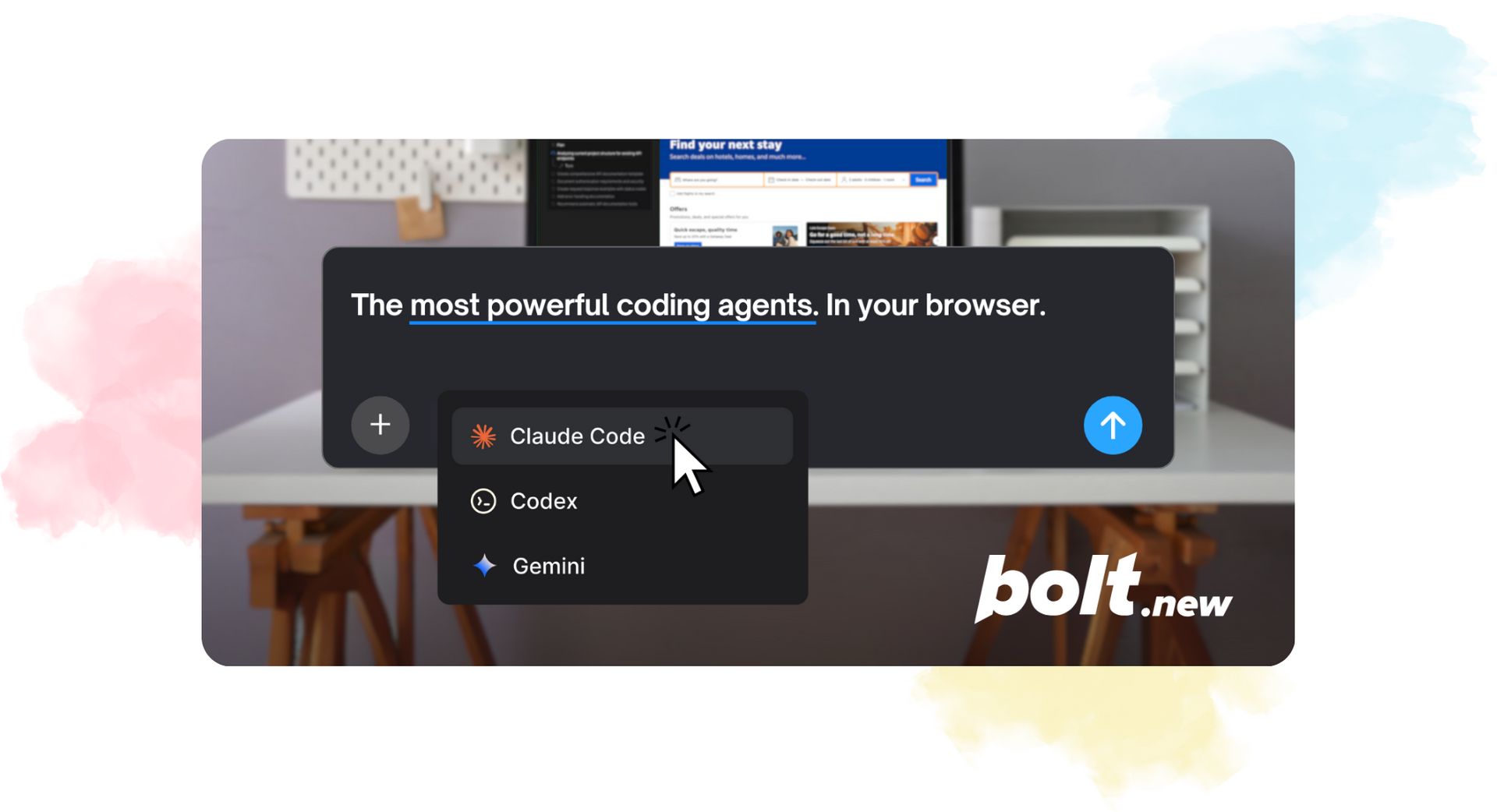

Let’s be honest: most vibe coding tools are toys.

Fun at first, but often get stuck in endless error loops, infrastructure headaches, and projects collapsing under their own weight.

Meet Bolt.new: the #1 professional vibe coding platform, trusted by product teams at 72% of the Fortune 500.

Bolt puts the most powerful coding agents and enterprise-grade infrastructure directly in your browser:

98% fewer error loops

Production-ready backend from day one

Pro-level power. Simple and intuitive chat interface.

Let Bolt do the heavy lifting so you can focus on your vision, not fight errors.

This is sponsored content.

We romanticize the founder who dreams of bold ideas. We think we’re one idea away from a billion dollar company. But every technological leap in history has not been constrained by ideas, but by materials.

For decades, materials innovation lay under the purview of governments and academia. New materials were developed in federal labs and universities through a slow process, detached from commercial timelines. Today, that is no longer the case. Rather, materials innovation can be the competitive advantage for companies building in DeepTech.

Today, we’ll take a look at just how fundamental advanced materials are to key DeepTech sectors.

“Advanced materials” is an intentionally broad term, since materials science has applications across many industries and encompasses many different types of materials.

Various alloys and metals in blocks

When ages of human civilization are named after the different metallurgical advances, it is evident that metal and alloys make up the backbone of civilization. However, unlike prior millennia, breakthroughs occur at the microscopic level. Advancements here impact almost every field, from energy to manufacturing to transportation. The importance of metals has driven geopolitics for centuries, with various issues stemming from mining and industrial secrecy.

While often considered fragile, ceramics and glasses may be the strongest choice depending on the application. They enable applications from turbine blades to thermal shielding to enhanced telecommunications. For example, fiber optic cables have made glass the go-to way to facilitate transmissions. They also have significant usage in radiation practices such as imaging. Modern ceramic science focuses on toughening the mechanisms they exist in and improving defect control.

Polymers today mostly consist of petrochemicals, chemicals derived from petroleum. Being lightweight and chemically created, they play significant roles in the infrastructure, defense, and healthcare. Environmental concerns regarding petroleum have resulted in significant pushes toward sustainability, with bio-derived and recyclable polymers emerging as economically viable alternatives.

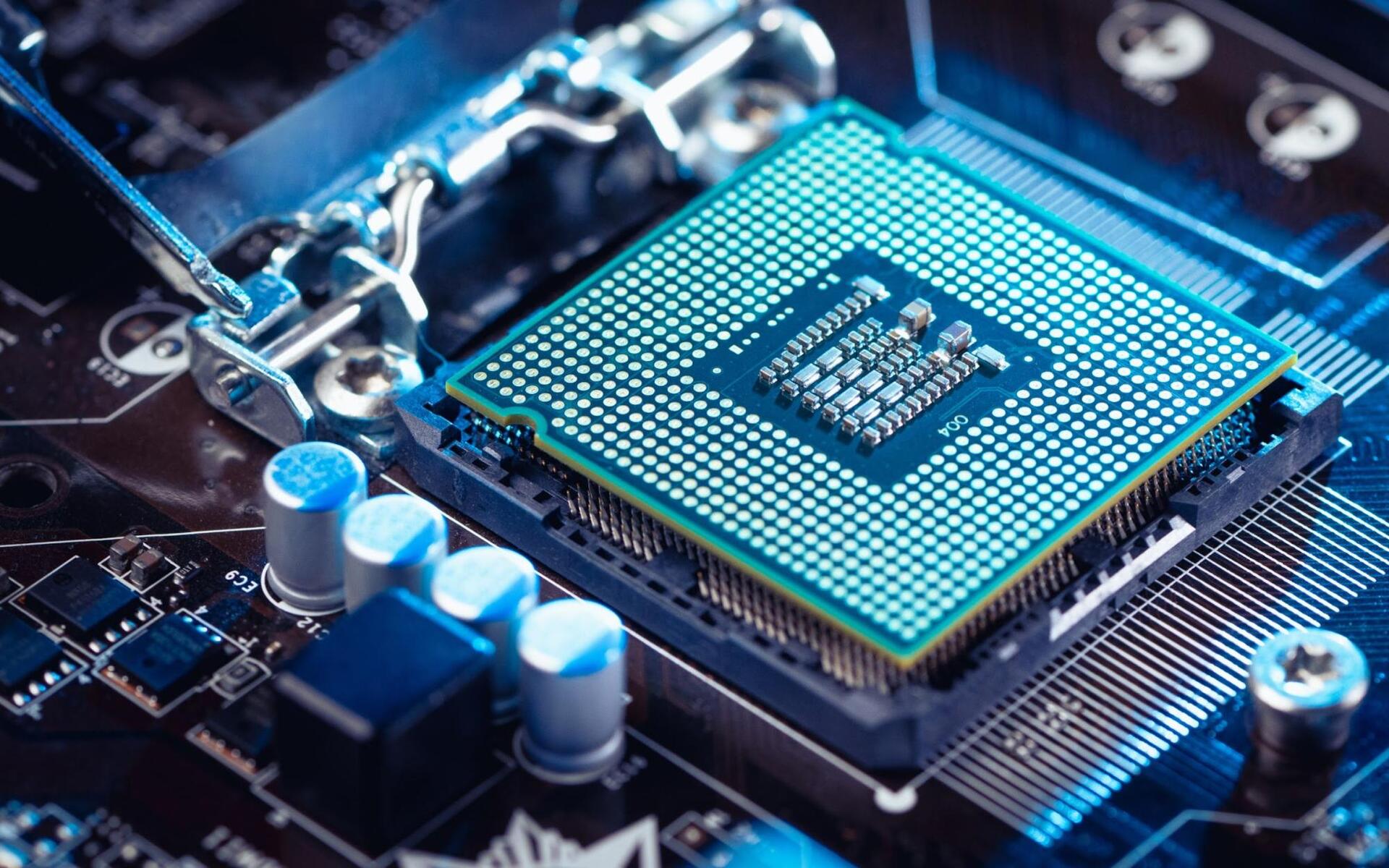

The focus on AI has put semiconductors in the limelight. Traditionally made of silicon, semiconductors underlie computing. However, one possible version of the future sees materials innovation that replaces silicon as the primary material. Since advancements in AI computing have strong promise, most investor money within advanced materials is spent toward semiconductors.

A semiconductor

Carbon fiber is well known for its light weight and durability, but other carbon-based materials have far-reaching applications. At the nanoscale, graphene and carbon nanotubes have been engineered for exceptional conductivity and strength, which offer benefits in electronics and structural reinforcement. Other applications in aerospace and other transportation sectors benefit from unmatched performance ratios offered by carbon composites. Additionally, given the ability to use carbon from carbon emissions, there are multitudes of ways to find carbon and manufacture them.

These materials exist between solid and liquid states, such as gels, foams, and other deformable materials. They are often chosen because they respond dynamically to external stimuli unlike rigid materials, desirable for certain medical and defense applications.

Biomaterials are designed to interact directly in and with living systems, giving them clear use cases in medicine. While implants are one of the most known uses, drug delivery systems and other therapies utilize biomaterials for their processes. They are also used for environmental remediation and agriculture, a rapidly growing space.

Lastly, composites categorize a mixture of these materials to achieve properties that no single material can deliver. Scaling composites reliably is one of the hardest challenges in advanced manufacturing, but it offers the highest return when done successfully.

Advanced materials used to sit in labs, either in college, government, or the sparse amount of corporate R&D labs. While Dupont invented synthetic textiles in the early 20th century, it took until post-WWII for it to become commercially available. Bell Labs invented the transistor in the 1940s, but it took another decade for it and semiconductors to be feasible. There are countless examples of advanced materials rotting in labs, but today that is changing.

The core of this shift is a tighter feedback loop between theory, simulation, synthesis, and final production. With new computational abilities, researchers can digitally model atomic and molecular interactions instead of using the traditional trial-and-error method. Machine learning (along with robotics and automation) also speeds up discovery and more accurately predicts results prior to synthesis. New technology solves the “Valley of Death,” which occurs when products fail to scale in the real world.

Altogether, this faster cycle of invention produces feedback quicker, and this flywheel has moved up development timelines. Tangentially, this makes failure less likely and encourages venture funding by replacing these types of startups within VC’s risk profiles.

Today, materials are co-developed by universities, startups, and large corporations in parallel, rather than sequentially.

Previously, software and consumer products offered greater success to investors, given the shorter time to returns. Now, with materials acting as bottlenecks to progress in key industries, the strategic value of materials innovation has increased. Investors, taking notice, now recognize that controlling the physical layer can create durable, defensible competitive advantages.

Government policy shifts have also facilitated the changing investment in the space. With increasing geopolitics in national resilience, there is a broader mandate, along with new government incentives, to innovate in previously ignored sectors such as supply chain, semiconductor independence, and new energy.

While new technological advances and capital appear to be an unstoppable force, the laws of physics are still an immovable object. Even though the probability of success has increased, many promising materials fail when tested. In many cases, the synthesis pathway becomes infeasible at scale, requiring entirely new processes that were never considered during discovery. Moreover, scaling the supply chain is difficult, given that many materials require inputs that make the whole process exposed to global supply chain dependencies. And that’s without considering the environmental, regulatory, and publicity risks they bring.

On the regulatory side, navigating certification and qualification cycles remains a stagnant process. Materials must prove performance and reliability over time and under stress, leading to the possible yearslong certification process. To complicate matters, a single substitution or minor statistical error can trigger a complete recertification or cancellation of the project. This creates a conservative engineering culture, empowering incumbents who have greater risk tolerance and capital to spend. Startups, often rushed, must contend with additional time and pressure.

The challenges are being diminished with new processes and new willingness to invest. Just as prior industries faced similar challenges, startups have found a way to thrive and dominate. The metaphorical dam has begun to crack, allowing new capital and innovation to flow.

Real-world impact is the byproduct.

Across different industries, advanced materials act as force multipliers, enabling systems that couldn’t exist before.

Defense capabilities are increasingly determined by materials. Performance is almost exclusively determined by the materials that are used to create products. For example, advanced materials like carbon nanotubes and ceramics enable lighter and more protective armor, new heat-resistant coatings allow vehicles to achieve speeds previously too fast to hit, composites reduce radar signatures of defense vehicles, and new electronic materials allow development of sensors. Defense is uniquely intolerant of failure, which makes materials qualifications slow, but extraordinarily sticky when adopted.

Energy powers all industries, as we discovered last time on DeepCorner. From the smallest batteries to the entire power grid, innovation in advanced materials means greater power efficiency and output. Concurrently, we are living through an energy transition to renewable energy (like wind, solar, and hydroelectric) and the almost limitless nuclear power. All of these face limitations, and advanced materials enhance them to be even more profitable and sustainable.

With transportation, weight, strength, and durability are the most important properties to enhance. New composites bring strength and durability at a fraction of the weight. This can lead to greater fuel efficiency and range of transit. New alloys bring similar attributes by making up engine components that have to function in high-heat environments. Aerospace is specifically enhanced by composites that have driven significant reductions in fuel usage and range in planes and polymers behind more sustainable fuel alternatives.

Advanced materials enable additive manufacturing (aka 3D printing), allowing parts to be printed in previously impossible geometries. Robotics requires lightweight materials that can sustain repeated use in the manufacturing process, and alloys and composites can fulfill those functions with incremental gains.

Robot made of composites conducting advanced material research

There is only so much smaller a transistor can go, and finding gains will come by changing the underlying materials. Additionally, silicon scaling faces thermal and electrical limits, forcing the industry to look at other materials that might not be economically viable yet. Besides this, new photonic materials can lead to faster computation and new memory systems can be discovered.

New climate solutions face financial constraints that limit profitability and viability for investment. These systems operate at massive scale and have razor-thin margins, making material durability and efficiency supremely important. New materials stand to help here. One place to look out for is emissions reductions. Carbon capture and storage has developed in recent years, and as we look at other ways to reduce and recycle used materials, there is potential to reuse past products for innovation.

Biomaterials enable implants and drug delivery systems that fit into the body without rejection. New medical imaging technology, too, benefits from materials innovation. Other forms of advanced materials play a role in medical applications, and even with long regulatory timelines, the sector rewards reliability over novelty.

In deep-sea and subterranean systems, immense pressures and volatility of surrounding mean materials need to be able to hold and function. In space, where speed is measured in lightyears and distance is in millions, speed and reliability are at the core of material engineering. Extreme radiation and temperature are just some factors in these uncertain environments, and this is where materials are pushed to the absolute limits.

Both power and computation face similar bottlenecks. OpenAI CEO Sam Altman and Nvidia CEO Jensen Huang have warned that demand is outpacing the physical limits of current chips, while the International Data Corporation warns of a global data storage crisis. The solution is re-engineering the physics over scaling current infrastructure. PsiQuantum is leading this by moving from electron-based silicon to photon-based architectures. By utilizing proprietary glass and semiconductor technologies, it is bypassing thermal limits to create quantum computers that are faster and energy-efficient.

Data storage faces a similar "capacity crunch," with magnetic drives hitting atomic limits. The fix is a pivot to glass and ceramics. Microsoft’s Project Silica and Cerabyte are replacing magnetism with optical data encoding. This creates "eternal storage" that is impervious to heat and requires zero energy to maintain, solving the data crisis by writing it into materials that last millennia.

Finally, energy storage is breaking its theoretical caps by swapping materials. Sila Nanotechnologies is replacing standard graphite anodes with silicon, boosting battery density by 20% to 40%. Meanwhile, Form Energy is utilizing iron-air chemistries to store grid-scale energy via a process it calls "reversible rusting."

Circularity is often viewed as a logistics problem, but at its core, it is a materials science challenge. The goal is a complex form of recycling called molecular reclamation that uses advanced physics to separate atoms from waste. Startups like Cyclic Materials and Nth Cycle are building solutions here. These advanced processes (electro-extraction and hydrometallurgy) eliminate the need for destructive open-pit mining and toxic tailings (waste), proving that the most sustainable materials are the ones we already have.

On the organic side, advancement lies with catalysts and synthetic biology. Air Company utilizes proprietary catalysts to transform captured CO2 into aviation fuel, while Samsara Eco employs AI-designed enzymes to break down plastics into their original monomers for infinite reuse. These innovations combined assist the world in reusing past resources.

The biggest strategic winners will emerge in defense and space. These sectors possess the largest budgets and the most intolerant environments, making materials the single point of failure for mission success.

A rocket launch

Hermeus and major defense prime contractors are battling the "heat wall," developing ultra-high temperature ceramics and refractory alloys that allow airframes to withstand hypersonic speeds that generate temperatures that would melt standard aluminum instantly. Simultaneously, the space sector is fighting the "rocket equation," where additional mass requires disproportionately more propellant to reach the same speed. The winners are pushing carbon composites and lithium-aluminum alloys to new limits, creating structures that offer steel-like strength at a fraction of the weight while also innovating radiation-hardened electronics to survive the harsh vacuum of deep space.

There is little thought given to how our phones were developed to be these pocket-sized supercomputers or how we went from the first air flight to the moon in 60 years. The underlying pattern is the development of society by advancements in materials, and such progress will continue to shape the future and reward those who harness them.

Advanced Material [ScienceDirect]

What are Advanced Materials? [ICL Group]

Looking forward to the next DeepCorner? |